TECHNOLOGY DRIVEN –sourcing and manufacturing for latest cost-effective cooling tower parts and components around the world.

TYH Series.

Cooling towers are CTI Certified. It comes with HDGS structure with efficient film fill. Belt and pulley design. Tower ranges available from 100RT to 1,500RT per cell.

TSF Series.

Single flow , Induced draft cross flow design offers energy in a small footprint installation. It comes with high efficient film fill fitted into HDGS structure. Towers ranged from 100RT to 800RT per cell.

TSD Series.

This Series is the best used when there is space constraint. Air flow is dis-charged side ways. It comes with high efficient film fill fitted into HDGS structure. Towers ranged from 100RT to 800RT per cell.

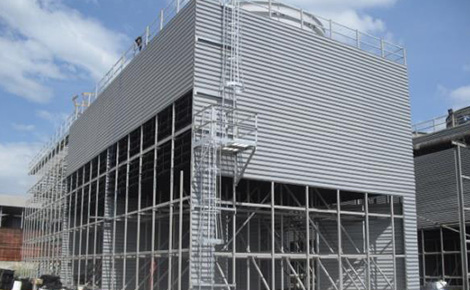

TCX Series.

Cooling towers are made with heavy duty steel using latest film fill technology. Excellent cooling tower for robust industries. Towers ranged from 100RT to 2,000RT per cell. Stainless steel structure and customer sizes are available.

TCCF Series.

TCCF Series Induced draft ,Counter flow design with low pump head requirement. It is made of HDGS structure with film fill. Towers ranged from 100RT to 2,000RT per cell. Stainless steel structure and splash fill available as an option.

TYN Series.

Closed circuit cooling towers are used when high water quality is required for circulating water in the system. Structures are made out of HDGS. Bolt copper and HDG carbon steel coils are available.

TCI Series.

CounterFlow, Film Type design Casing and Water Basin are made of Strong, durable, UV resistant and non-corrosive Fiberglass. Ranged from 10RT to 1,000RT per set.

Counterflow,Induced Draft TCF Series.

Pultruded FRP are used for the cooling tower structure. It can be fitted with splash fill or film fill. Each cell size can be designed to take up to 7,000 m3/h of circulating water.

Counterflow,Induced Draft TCC Series.

Concrete mechanical draft of various size . It can be fitted with film fill or splash fill. It is suitable for use on most industries such as petrochemical ,power plant ,biomass and many more.

Counterflow,Induced Draft TCT Series.

Treated timbers are used for the cooling tower structure. It can be fitted with splash fill or film fill. Each cell size can be designed to take up to 7,000 m3/h of circulating water.

Crossflow,Induced Draft

TC-100/150 Series. Cooling tower structure are made out of treated timber or pultruded FRP. It is splash fill design where pool water quality. Max flow is 1,100 m3/h per cell.

Crossflow,Induced Draft TC-SIG Series.

Available in treated timber, pultruded FRP. and HDG Steel structure, this series is highly efficicent and low maintenance. It comes with film fill design and suitable for medium size industries and large HVAC projects. Max flow is 2,600 m3/h per cell.

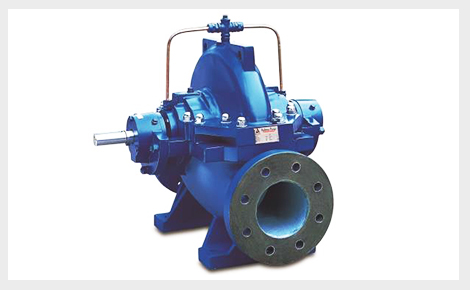

S/SH Double Suction Split Casing

Flow : 50 - 6,250 m3/hr

Head : 9 - 140 m

ES End Suction Centrifugal

Flow : 4 - 460 m3/hr

Head : 5 - 98 m

S/SH Double Suction Split Casing

Flow : 50 - 6,250 m3/hr

Head : 9 - 140 m